As a dedicated player in the industrial LED smart lighting sector, ROYAL Light leverages customized technologies to transform "LED illumination + IoT control" into practical solutions tailored for heavy industry, chemical engineering, automotive manufacturing, and other scenarios, addressing the pain points of traditional lighting. Below is a streamlined breakdown of its value from three aspects: core technologies, scenario-based implementation, and compliance & environmental protection.

Voltage fluctuations in industrial environments (e.g., 180V-250V) tend to damage lamps. ROYAL Light's 100V-240V wide-voltage driver chip has a tolerance range 1.6 times that of the industry average. When voltage fluctuates by ±15%, the light output remains stable (with a fluctuation ≤3%). Additionally, 6KV surge protection is integrated to resist high-voltage impacts from lightning strikes.

ROYAL Light's smart lamps integrate radar, temperature-humidity, and other sensors, and connect to the IoT to achieve:

· Dynamic Dimming: Brightness switches triggered by human movement, helping a logistics park reduce annual electricity consumption by 40%;

· Environmental Alert: In chemical workshops, lamps turn red and link to ventilation systems when dust concentration exceeds standards;

· Fault Prediction: Real-time data monitoring helped a heavy industry enterprise reduce unplanned downtime by 70%.

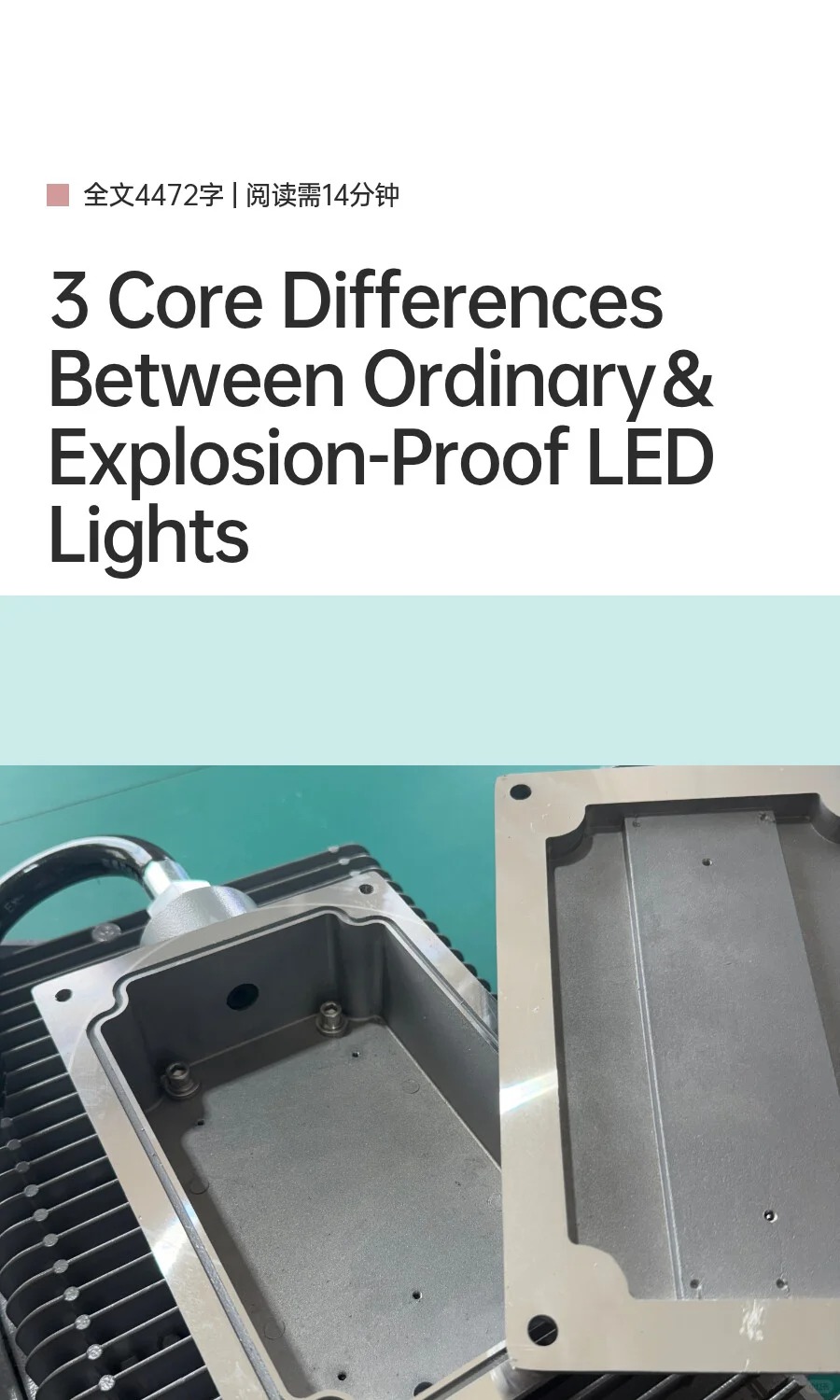

ROYAL Light's smart explosion-proof lamps have obtained ATEX/IECEx certifications (EU/International Explosion-Proof Standards). Their explosion-proof housings can withstand 2000℃ explosion pressure, and smart modules are isolated from circuits.

For cold chain warehouses, ROYAL Light's low-temperature adaptive lamps use low-temperature grease and preheating modules, enabling a 0.2-second start-up. Their service life still reaches 8 years even in -30℃ environments.

ROYAL Light's high-color-rendering smart industrial lamps (color rendering index Ra≥90) support color temperature switching: 6000K cool white light for inspection (to reveal defects) and 4000K neutral white light for welding (to protect eyes). After application in BYD (Hefei) Welding Workshop, the part qualification rate increased by 2.3%.

ROYAL Light's lamps have obtained CCC (China Compulsory Certification), CE (EU Conformity Mark), RoHS (Restriction of Hazardous Substances), and other certifications. A German customer completed customs clearance in only 4 days (industry average: 7-10 days).

The lamps adopt a modular detachable design, with a material recycling rate of 92% (industry average: 65%) and no lead or mercury content.

1. Scenario Adaptation: Choose wide-voltage models for unstable voltage, and smart explosion-proof models for explosion-proof scenarios;

2. Total Lifecycle Cost Calculation: Although ROYAL Light's lamps cost 15%-20% more upfront, their total 5-year cost is 40% lower;

3. Compliance Document Check: For export, confirm certifications required by the target market.

ROYAL Light's core advantage lies in making "smart lighting" truly serve production—this is also the key reason it has provided services to over 50 leading enterprises, including China Aerospace Construction and BYD.