As ROYAL Lighting, a company deeply engaged in the global LED lighting industry for years, we have received many urgent requests for help from customers: "Even with CE certification, our LED lights were still detained when entering Europe," "Unstable voltage in Southeast Asian factories burned out 20 LED lights in a week," and "We were fined by local environmental authorities for throwing used LED lights into regular trash bins." These issues are not due to "poor LED quality"—they stem from overlooking three critical dimensions that are easily neglected: certification scope matching, power environment adaptation, and environmental compliance. Today, drawing on over 180 cross-border and domestic cases, we break down 3 core safety and compliance misconceptions in LED procurement to help you select LED lights that "pass customs smoothly, operate safely, and meet environmental policies." We also explain how ROYAL addresses these pain points through end-to-end optimization.

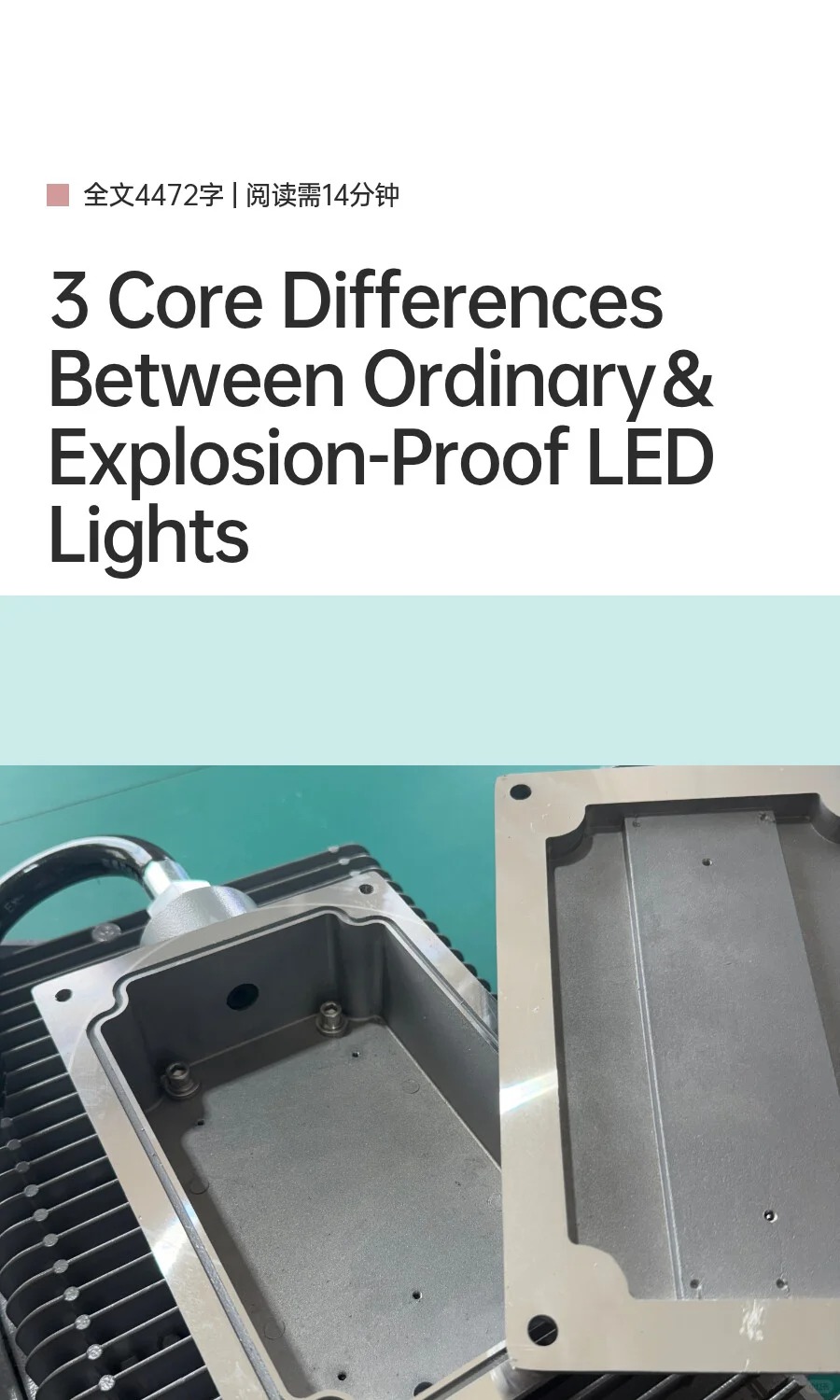

Many customers assume that "as long as LED lights have CE certification, exporting to Europe will be problem-free." However, their goods are often detained during customs clearance because "the certification scope does not match the product type"—for example, using CE certification for ordinary panel lights to export explosion-proof LED lights, or failing to include the ERP Energy Efficiency Directive in the certification. The root cause is a lack of understanding that "CE certification is not a ‘one-size-fits-all certificate’ but is ‘segmented by product type’."

Confusing the "segmented standards of CE certification": Ordinary LED lights require CE-LVD (Low Voltage Directive) + CE-EMC (Electromagnetic Compatibility) certification, but explosion-proof LED lights additionally need ATEX certification. LED lights exported to the EU must also include ERP energy efficiency certification (since 2023, ERP energy efficiency must reach Class A). Missing any of these will result in customs clearance failure.

1. Segmented Certification Coverage by Product: We obtain exclusive certifications for different LED products—ordinary panel lights have three certifications (CE-LVD + EMC + ERP), explosion-proof floodlights add ATEX certification (covering hazardous areas of Zone 1/2/21/22), and stage lights supplement CE-RoHS certification (restricting hazardous substances). A German customer who purchased ROYAL’s explosion-proof LED lights completed customs clearance in only 4 days (compared to the industry average of 7 days) thanks to complete certifications.

2. Pre-Export Certification Verification: We provide customers with "free certification matching checks." For example, if a customer intends to export LED spotlights to French supermarkets, ROYAL will verify in advance whether "the certification includes ERP Class A energy efficiency" and "whether the test report bears the seal of an EU Notified Body (e.g., TUV)" to prevent customers from falling into pitfalls due to a lack of certification knowledge.

3. Synchronized Supporting Customs Clearance Documents: Each batch of exported LED lights is accompanied by "certification reports + Declaration of Conformity (DoC) + Certificate of Origin," with documents clearly stating that "the product model is fully consistent with the certified model" (a common issue with ordinary suppliers is model mismatches). An Italian customer reported, "We have never been asked by customs to supplement documents when using ROYAL’s clearance materials."

Before exporting LED lights, always ask the supplier, "Does the certification cover the specific type of your product (e.g., explosion-proof/ordinary/stage lights)?" and request "the first page of the certification report + the page with the model information" to confirm consistency with the purchased product. For exports to the EU, additionally verify whether "ERP energy efficiency certification is included."

Many customers experience "LED burnout from sudden voltage spikes" or "LED lights failing to turn on due to low voltage" when using LED lights in regions with unstable power (e.g., Southeast Asia, the Middle East). They often attribute this to "poor LED quality," but the actual issue is selecting "fixed-voltage models" (only 220V or 110V) without considering local power fluctuations.

Overlooking "differences in power environments across regions": For example, China uses 220V ±10%, while India uses 230V ±20% and some parts of Southeast Asia have fluctuations between 110V-240V. Fixed-voltage LED lights are prone to burnout outside their fluctuation range, whereas wide-voltage LED lights (adaptable to 100V-240V) handle fluctuations more safely.

1. Full-Series Wide Voltage Design: All ROYAL LED lights adopt "100V-240V wide-voltage drivers," with a tolerance range 60% wider than ordinary fixed-voltage drivers. In an Indian factory with voltage fluctuations between 180V-250V, ROYAL LED lights operated normally, while 15 of the competitor’s fixed 220V LED lights burned out within a week.

2. Surge Protection Upgrade: The driver power supply includes a built-in "6KV surge protection chip" (ordinary LED lights typically use 4KV chips), which resists damage from sudden voltage spikes. A Thai customer experienced a lightning strike that caused a sudden voltage surge—ROYAL’s LED lights remained undamaged, with only the circuit breaker tripping.

3. Voltage Adaptation Consulting Services: For customers unsure about local voltage, ROYAL provides a "power environment guide for the target region" (e.g., 230V in the Middle East, 110V in most of South America) and can customize "special voltage models" (e.g., 380V industrial voltage). ROYAL’s 380V explosion-proof LED lights used in a Middle Eastern oil field have operated without voltage-related damage for 2 years.

Before purchasing LED lights, confirm "the voltage range of the target usage region" and prioritize "100V-240V wide-voltage" products. For regions with significant voltage fluctuations (e.g., factories, remote areas), ask the supplier for "surge protection rating" and prioritize models with ≥6KV protection.

Many customers believe that "LED lights are maintenance-free and can be left unattended after installation." As a result, after 1 year of use, LED housings accumulate dust, bathroom LED lights are damaged by moisture, brightness decreases, and short circuits occur. This is due to overlooking that "LED lights also require ‘environment adaptation’ and ‘daily cleaning’."

Assuming that "long LED lifespan = no need for care." However, dust accumulation impairs heat dissipation (accelerating light decay), and humid environments cause circuit failures. LED lights in different spaces require targeted "maintenance-friendly designs."

1. Easy-to-Clean Lamp Body Design: All ROYAL LED lights feature a "nano dust-proof coating." Dust can be wiped off with a dry cloth, reducing cleaning frequency by 80% compared to ordinary lamp bodies (where dust adheres easily). After an office building adopted ROYAL LED lights, the frequency of cleaning by janitors decreased from once a month to once every 3 months.

2. Humid Environment Adaptation: LED lights for humid areas (e.g., bathrooms, kitchens) use IP65 waterproof design (ordinary LED lights typically use IP44). Silicone gaskets seal the joints of the lamp body to prevent moisture from entering and causing short circuits. A residential community resident reported, "ROYAL’s bathroom LED lights have been used for 4 years without moisture-related malfunctions."

3. Detachable Cover Design: The ceiling lamp cover uses a "snap-on installation" that can be removed for cleaning without tools—avoiding the hassle of disassembling ordinary integrated LED lights (which often require screwdrivers and risk damaging the lamp body during disassembly).

For dusty areas (e.g., workshops, living rooms), prioritize LED lights with "nano dust-proof coatings." For humid areas (e.g., bathrooms, kitchens), confirm the waterproof rating is ≥IP65. Choose LED lights with "detachable covers" to simplify regular cleaning.

A high-quality LED product should not only be "bright and durable" but also "pass customs smoothly, operate safely in diverse power environments, and be easy to maintain." The key to achieving this lies in three easily neglected dimensions: "certification scope matching, wide voltage adaptation, and maintenance-friendly design."

ROYAL has long adhered to "end-to-end compliance and safety design": Whether it’s explosion-proof LED lights exported to the EU, wide-voltage panel lights for Southeast Asia, or easy-to-clean LED lights for domestic homes, all products undergo "certification verification, power adaptation testing, and environmental resistance inspections." We also provide value-added services such as "export compliance consulting, voltage customization, and maintenance guidance" to ensure customers use LED lights with confidence and no hidden risks.

ROYAL– Every LED stands up to compliance inspections, safety tests, and maintenance needs.