When many industrial clients purchase lighting, they easily fall into the trap of "focusing only on unit price and ignoring long-term costs." What they overlook is this: inappropriate lamps may reduce production efficiency, frequent maintenance adds hidden costs, and outdated equipment wastes energy. Breaking free from the role of a "mere supplier," Royal Lighting offers full-lifecycle services covering preliminary diagnosis, mid-stage adaptation, and post-implementation operation & maintenance. This transforms lighting from a "one-time purchase" into a "long-term value-adding asset"—and this is the core reason why countless clients choose Royal Lighting.

Royal Lighting never approaches clients with a "standard quotation sheet" directly. Instead, we first conduct on-site visits to identify the "hidden needs" of the production scenario:

Last year, a heavy machinery manufacturing plant contacted Royal Lighting, saying their workshop lamps were "not bright enough" and they wanted to replace them with high-power models. However, after arriving on-site, Royal's engineers didn't rush to recommend products—instead, they did three key things:

Data Measurement: Used professional equipment to test the illuminance and color temperature of the machine tool work areas;

Process Observation: Tracked the production rhythm and discovered that during night shifts, light reflection made it hard to read machine tool scales, leading to part precision errors exceeding 0.1mm;

Cost Calculation: Helped the client calculate the energy consumption of their old lamps—they were using 400W metal halide lamps, and 100 such lamps cost over RMB 30,000 in monthly electricity bills. With a lifespan of only 8,000 hours, the lamps needed replacement every six months.

Based on this diagnosis, Royal did not recommend high-power lamps. Instead, we customized a combination of "300W industrial high-bay lamps + local supplementary lamps":

6000K neutral white light was used in work areas to reduce visual fatigue;

Anti-glare shields were added to lamp bodies to avoid light reflection.

In the end, illuminance met standards, single-lamp energy consumption decreased by 25%, the client saved RMB 7,500 in monthly electricity bills, and part precision errors were controlled within 0.05mm.

The "specificity" of industrial scenarios often lies in the details. When implementing solutions, Royal prioritizes "not disrupting production and aligning with on-site details":

A food processing plant had two special requirements when purchasing workshop lighting:

Lamps needed to be oil-resistant (the workshop is cleaned daily, and oil easily adheres to lamp bodies);

Installation must not delay production (the production line runs 24/7, and a 1-hour shutdown causes over RMB 50,000 in losses).

Royal's solution was highly "scenario-aligned":

Product Adaptation: Lamp surfaces were coated with Teflon oil-resistant coating, allowing oil stains to be wiped off easily. Cleaning time per lamp was reduced from 1 hour to 10 minutes;

Installation Adaptation: Arranged "off-peak night installation"—a 5-person team was divided into 3 groups, each responsible for one production line. Working from 10 PM to 5 AM, they completed the installation of 120 lamps in 3 days, with no impact on daytime production;

Acceptance Adaptation: Instead of delivering immediately after installation, we stayed with the client to observe 3 consecutive production shifts. We adjusted the angles of 8 lamps (to prevent direct light from hitting production line workbenches) and only concluded the process when workers reported "visual comfort with no impact on operations."

The "value" of industrial lamps becomes more evident 3–5 years after use. Royal's services do not end with "installation completion"—we continue to follow up on operation & maintenance and even help clients with "old lamp upgrades":

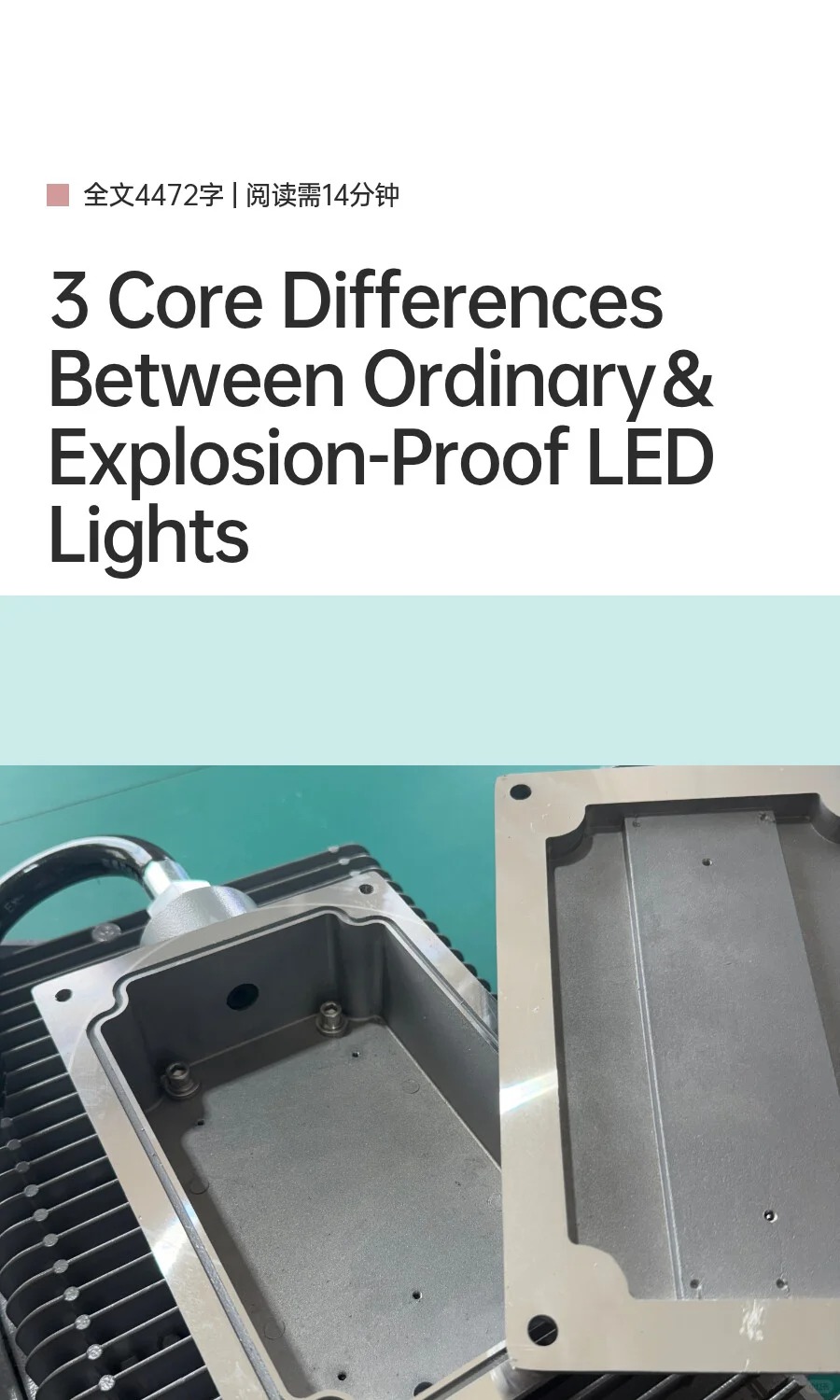

A long-established chemical enterprise installed Royal's explosion-proof lamps in 2021. Earlier this year, they contacted us saying "one or two lamps have dimmed, and we want to replace them with new ones." After arriving on-site, Royal's engineers did not directly promote new lamps—instead, they took two key steps:

Operation & Maintenance Optimization: After inspection, they found that 80% of the lamps were not "broken"—their surfaces were covered in chemical dust. After cleaning, brightness was restored to 85%. At the same time, they adjusted the circuits of 15 lamps (some lamp drivers had absorbed moisture due to voltage fluctuations in the workshop). The problem was solved in just 2 days, helping the client save nearly RMB 100,000 in replacement costs;

Upgrade Recommendation: In response to the client's need for "energy savings," we recommended replacing the remaining 20% of outdated lamps with Royal's new "smart explosion-proof lamps"—these can be connected to the workshop's IoT system for remote monitoring of lamp operation status and dimming based on production load. After a trial, the client saved an additional RMB 3,000 in monthly electricity bills.

For industrial clients, lighting is never a trivial "one-and-done purchase"—it is a "long-term asset" related to safety, efficiency, and costs. Royal Lighting's core value lies in transforming our role from "selling a lamp" to "managing the full lifecycle":

· In the preliminary stage, we help clients "avoid pitfalls";

· In the mid-stage, we help clients "adapt to scenarios";

· In the post-implementation stage, we help clients "add value."

This ensures every investment is converted into tangible benefits—and this is why more and more industrial clients see Royal Lighting as a "long-term partner" rather than just a "lamp supplier."