"Just installed an LED light, and in only one year, its brightness has dropped by half—did I buy a low-quality product?" This is a common pain point faced by countless households and businesses when using LED lights. Recently, focusing on this core industry challenge, ROYAL Lighting has achieved a breakthrough through three key technologies—chip selection, heat dissipation design, and anti-sulfidation process—strictly controlling the lumen depreciation of LED lamps to within 5% after 5,000 hours. This not only solves the practical problem of "brightness attenuation" but also helps users avoid the consumption trap of "low price but short lifespan" with solid technology.

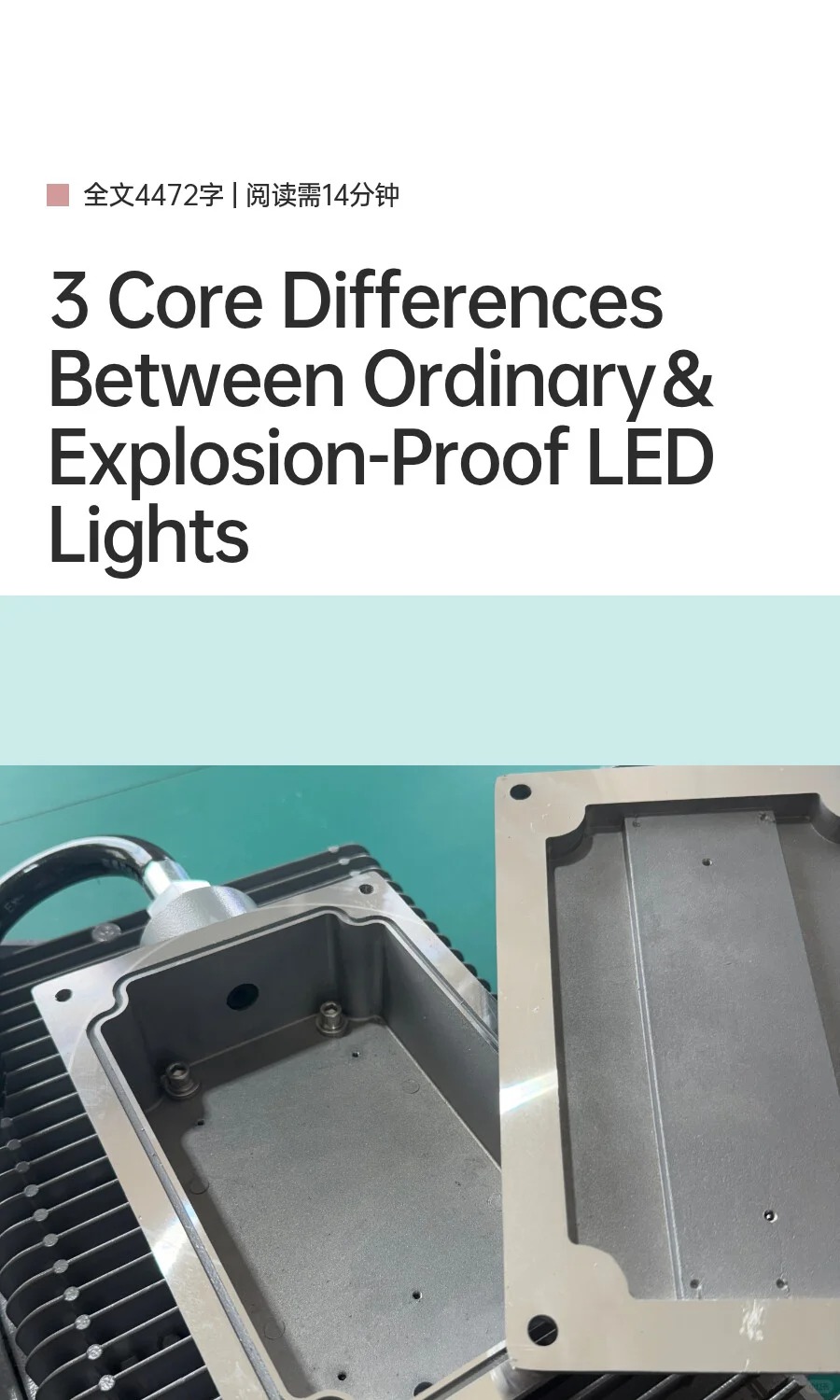

Many users simply attribute the "dimming over time" of LEDs to "low-quality products," but they overlook the technical core behind lumen depreciation. Manager Zhang of ROYAL Lighting, explains: "The rapid lumen depreciation of ordinary LEDs lies in three key factors: insufficient heat resistance of the chip, flawed heat dissipation structure, and lack of anti-sulfidation treatment. For example, when low-quality chips are used in environments above 60°C, their lifespan decreases by 50% for every 10°C increase in temperature; meanwhile, poor heat dissipation causes the internal temperature of the lamp to rise continuously, accelerating brightness attenuation."

Targeting the root causes of lumen depreciation, ROYAL Lighting has made precise breakthroughs in product R&D. Each technology directly addresses core issues, supported by clear data:

1. High-Efficiency Chip Selection: All LED products adopt high-efficiency chips, which have passed 120°C high-temperature aging tests. Their heat resistance is 40% higher than that of ordinary chips, enabling stable light emission within the normal operating temperature range of lamps (40-60°C) and reducing lumen depreciation caused by high temperatures at the source.

2. Aerospace-Grade Heat Dissipation Upgrade: The lamp housing features an aluminum honeycomb-shaped guide slot design, increasing the heat dissipation area by 3 times compared to traditional plastic housings. Combined with a built-in silicone thermal pad, it rapidly conducts heat from the chip to the housing, controlling the core internal temperature of the lamp below 55°C—20°C lower than that of ordinary lamps—greatly slowing down brightness attenuation.

3. Special Anti-Sulfidation Process: A dedicated anti-sulfidation coating is applied to the connection between the lamp holder and lamp beads, preventing sulfides in the air from reacting with metal components to form silver sulfide (which causes lamp beads to turn black and brightness to drop sharply). This process triples anti-sulfidation performance, making the lamps particularly suitable for humid/dusty environments such as kitchens, bathrooms, and factories.

To help users avoid lumen depreciation traps, ROYAL Lighting also shares practical purchasing tips:

1. Request Test Reports: Prioritize brands that can provide "5,000-hour high-temperature aging test reports," and focus on lumen depreciation data (≤5% is the standard for high-quality products).

2. Check the Heat Dissipation Structure: Avoid lamps with plastic housings; opt for products with aluminum housings and guide slot designs. After the lamp has been in operation for 1 hour, touch the surface—if it doesn’t feel scalding, its heat dissipation performance is better.

3. Reject "Three-No" Low-Price Products: LEDs without brand logos or parameter labels mostly use low-quality chips and lack anti-sulfidation treatment. Their lumen depreciation rate is 2-3 times that of regular products, which may seem cheap but end up costing more in the long run.

Currently, ROYAL Lighting’s anti-lumen-depreciation LEDs have obtained three major international certifications: CE, ATEX, and RoHS, covering all scenarios including household, commercial, and industrial use. Notably, despite the integration of three technical optimizations, the product price is only 8%-10% higher than that of ordinary LEDs, while their service life is extended by 50%, significantly improving overall cost-effectiveness. Leveraging this advantage, the order volume of its industrial-grade anti-lumen-depreciation LEDs in factories in the Yangtze River Delta and Pearl River Delta regions has increased by 25% month-on-month, and the commercial models have also become the first choice for chain supermarkets and hotels.

ROYAL Lighting’s anti-lumen-depreciation LEDs currently cover three major scenarios: household, commercial, and industrial. Among them, the industrial-grade anti-lumen-depreciation LEDs, with their ability to adapt to high-temperature and dusty environments, have seen a 25% month-on-month increase in orders from factories in the Yangtze River Delta and Pearl River Delta regions. Regarding price concerns, Zhang stated: "The three technical optimizations have not significantly increased costs. Through large-scale production, we have controlled costs within a reasonable range. Although the product price is only 8%-10% higher than that of ordinary LEDs, the service life is extended by 50%, resulting in higher overall cost-effectiveness."

LED lumen depreciation has long been a technical pain point in the industry. Through targeted technological innovation, ROYAL Lighting has not only solved the practical problem of "brightness attenuation" for users but also helped consumers establish correct purchasing awareness through popular science. This promotes the transformation of the lighting industry from "competing on low prices" to "valuing technology," providing a reference path for the high-quality development of green lighting.