In factory workshops, warehouses, and similar spaces, lighting fixtures may seem to “serve the same function." However, in environments with flammable and explosive substances—such as chemical workshops, gas stations, and underground coal mines—replacing explosion-proof lights with ordinary LED lights can create potential safety hazards. Many people wonder: since both emit light, what exactly sets ordinary LED lights apart from explosion-proof ones? And why must explosion-proof lights be used in hazardous environments? Combining practical cases in the industrial lighting field, we break down the core differences between the two to help you understand “which type of light to choose for different scenarios."

The core purpose of ordinary LED lights is “to emit light," while the core of explosion-proof lights is “to emit light while preventing explosions"—their design logics are fundamentally different.

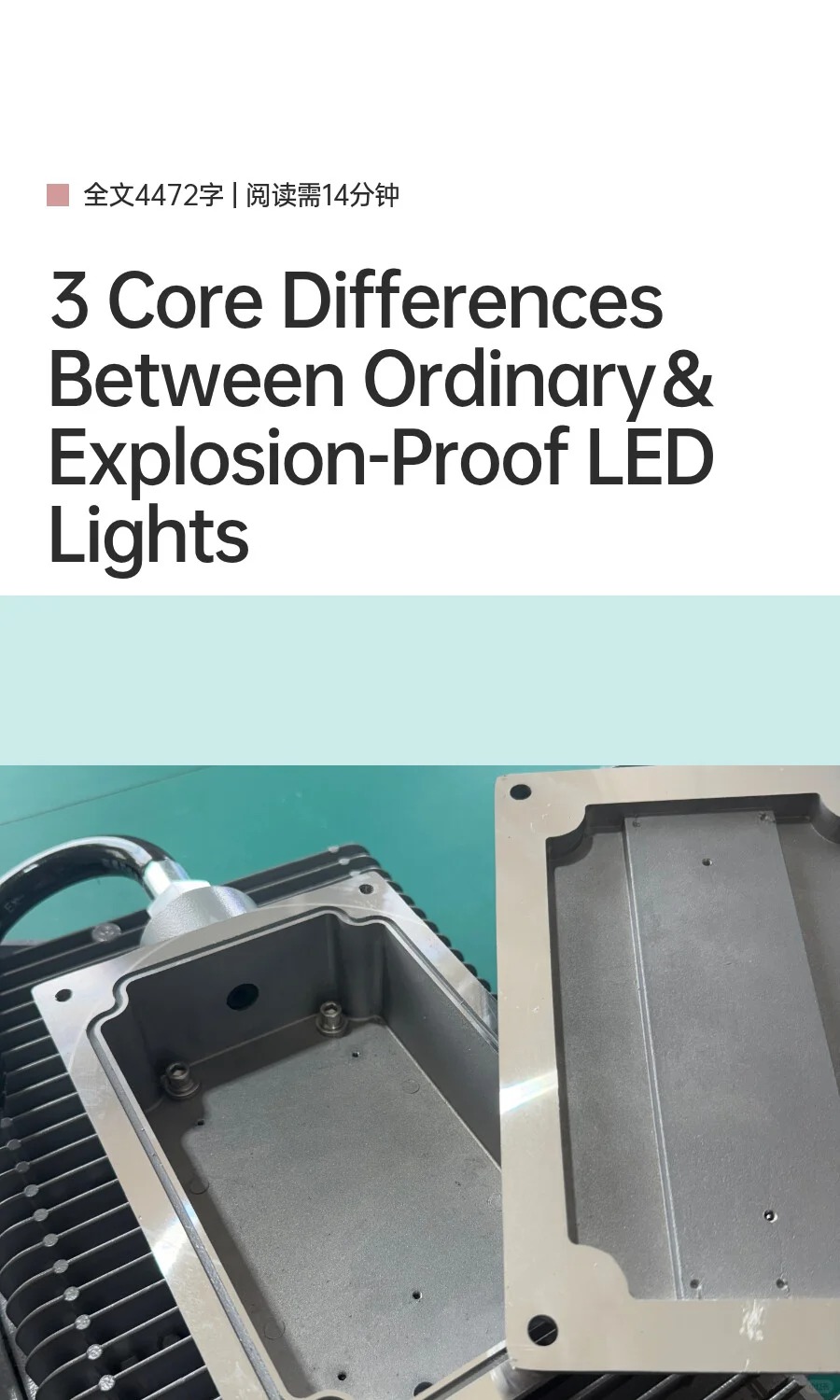

Ordinary LED lights have a simple structure: lamp beads, a driver circuit, and a plastic or aluminum alloy housing, with no special design for “explosion protection." For example, their heat dissipation holes are open; if flammable gases (such as methane or acetylene) are present in the environment, they can enter the lamp body through these holes. If the circuit shorts and generates sparks, it may ignite the gas and cause an explosion.

In contrast, the design of explosion-proof lights revolves around “interrupting the explosion chain" and includes at least two layers of “safety armor":

First layer: Flameproof enclosure

The enclosure of RAYA Lighting's explosion-proof lights is die-cast from high-strength ADC12 aluminum alloy, with a thickness 2–3 times that of ordinary LED lights. It can withstand 1.5 times the internal explosion pressure—even if a fault inside the lamp generates sparks that ignite infiltrated flammable gas, the enclosure can “contain" the flame and pressure, preventing them from leaking into the environment and avoiding a larger explosion.

Second layer: Intrinsically safe circuit

The driver circuit of explosion-proof lights uses current and voltage limiting designs to keep electrical parameters within “safe thresholds" (e.g., current ≤ 100mA). Even if the circuit shorts, the energy generated is insufficient to ignite flammable gases. RAYA Lighting's explosion-proof lights also add an “insulating barrier" between the circuit and the enclosure to further prevent sparks from coming into contact with the external environment.

In simple terms: Ordinary LED lights are “unprotected," while explosion-proof lights are “wearing explosion-proof suits"—their safety levels are in completely different tiers.

Checking certifications when choosing lights is key to distinguishing the two—ordinary LED lights and explosion-proof lights have vastly different “certification standards."

Ordinary LED lights only need to pass the mandatory CCC certification (covering basic requirements like safety and electromagnetic compatibility) to be marketed. This ensures, for example, that the lamp body does not leak electricity and does not overheat during normal use. This certification targets “conventional environments" and does not include assessments for flammable or explosive scenarios.

Explosion-proof lights, however, must obtain not only CCC certification but also explosion-proof certification from the National Center for Quality Supervision and Inspection of Explosion-Proof Products (marked as “Ex" domestically, and ATEX for the EU, IECEx internationally). How strict is this certification? Taking RAYA Lighting's explosion-proof lights as an example, they must pass three core tests:

Flameproof performance test: Flammable gas is injected into the lamp body, then ignited to check if the enclosure cracks or if flames leak out;

Temperature test: The lamp operates continuously for 48 hours, and the surface temperature of the enclosure is monitored—for example, in hydrogen-rich environments, the surface temperature must not exceed 100℃ (hydrogen's ignition temperature is 560℃, leaving a sufficient safety margin);

Insulation test: The circuit's insulation performance is tested in a humid environment (95% relative humidity) to prevent sparks caused by leakage.

Only after passing these tests can explosion-proof lights be labeled with specific explosion-proof grades such as “Ex d IIC T4" (suitable for high-risk gas environments like hydrogen or acetylene, with a maximum surface temperature ≤ 135℃). Ordinary LED lights have no such labels at all.

Many people think “explosion-proof lights are more advanced and can be used in all scenarios," but this is incorrect—their applicable scenarios have clear boundaries. Choosing the wrong one not only wastes money but may also be non-compliant.

Examples include:

Offices and ordinary workshops (e.g., furniture assembly workshops with no flammable/explosive substances);

Warehouses storing non-flammable items like cartons or plastic;

Outdoor areas such as municipal roads and parking lots.

These scenarios have no flammable gases or dust, so the basic safety design of ordinary LED lights is sufficient. Additionally, their price is 30%–50% lower than that of explosion-proof lights, offering better cost-effectiveness.

Based on the type of hazardous substance, they mainly apply to two types of scenarios:

Gas hazardous environments: Gas stations, chemical workshops (producing or storing gases like ethanol or methane), and gas-fired boiler rooms—these scenarios require explosion-proof lights with the grade “Ex d IIC."

Dust hazardous environments: Flour processing plants, underground coal mines, and plastic granulation workshops (with suspended flammable dust)—these scenarios require explosion-proof lights with the grade “Ex tb IIIC." The lamp body must prevent dust from entering to avoid spontaneous combustion caused by dust accumulation. RAYA Lighting's explosion-proof lights designed for underground coal mines also include anti-corrosion coatings to cope with humid, dusty environments.

It is particularly important to note: China's Code for Design of Electrical Installations in Explosive and Hazardous Environments clearly stipulates that explosion-proof lights meeting the required grade must be used in hazardous environments. Using ordinary LED lights is non-compliant—violators may face fines, and those responsible for accidents may bear legal liability.

Check if the environment has “hazardous substances": If there are flammable gases or dust → must use explosion-proof lights; if not → choose ordinary LED lights;

Check if the explosion-proof grade “matches the scenario": For gas environments, look for “Ex d IIC"; for dust environments, look for “Ex tb IIIC." Do not use “low-grade explosion-proof lights" for high-risk scenarios;

Check if certifications are “complete": Explosion-proof lights must have both “Ex certification + CCC certification"—neither is dispensable. Avoid buying “fake explosion-proof lights."

In short, choosing lights for workshops is not about “buying any bright light casually," but about “matching the solution to the environment's risks." Ordinary LED lights can meet conventional lighting needs, but in hazardous environments, only the “safety armor" of explosion-proof lights can uphold the bottom line of production safety.