When the demand for industrial lighting has long evolved from "illuminating spaces" to "empowering safety, energy efficiency, and production efficiency", Royal Lighting is constantly setting new industry standards with its cutting-edge technology, scenario-specific solutions, and unwavering pursuit of reliability. Building on its dual honors as a Top 100 Enterprise in China's Lighting Industry and a recipient of the China's Excellent Green Environmental Protection and Energy-Saving Product certification, Royal Lighting is redefining the core value of industrial lighting through scenario-based innovation and intelligent technology integration.

Royal Lighting's "reliability" is no empty claim; it stems from continuous R&D investment and refined engineering precision, achieving technological breakthroughs in multiple key areas:

In semiconductor cleanrooms, even a 0.1mm defect can cause million-level losses. Royal's Cleanroom-Specific LED Series specifically addresses such pain points:

Dust-Free Structural Design: Hermetically sealed, ventless lamp bodies paired with nano-dustproof coatings prevent dust accumulation, reducing workshop cleaning frequency by 60% and dust contamination rate by 92%;

High Color Rendering for Accurate Restoration: With an ultra-high color rendering index (Ra ≥ 98), it clearly reveals subtle color differences in chip metal coatings and 0.05mm scratches, increasing defect detection efficiency by 40%;

Anti-Interference Protection: Full-link electromagnetic shielding (metal shielding cover + twisted pair cables) meets EMC Class A certification, avoiding signal interference with lithography machines and wafer inspection equipment. After application in a chip factory, equipment false alarm rate decreased by 75%.

Facing extreme industrial scenarios such as high temperature, low temperature, and high corrosion, Royal's customized special lamps demonstrate strong adaptability:

For underground coal mines, lamps adopt corrosion-resistant stainless steel housings and IP68 waterproof rating, supporting low-temperature startup at -30℃ and operating continuously for 5 years without failure in humid environments with 95% humidity;

The high-temperature-resistant series designed for desert oilfields can operate stably in 85℃ high temperature and level-12 sandstorm environments. In a Saudi oilfield project, Royal's lamps achieved "zero maintenance for 5 years", far exceeding the industry's average maintenance cycle of 2 years;

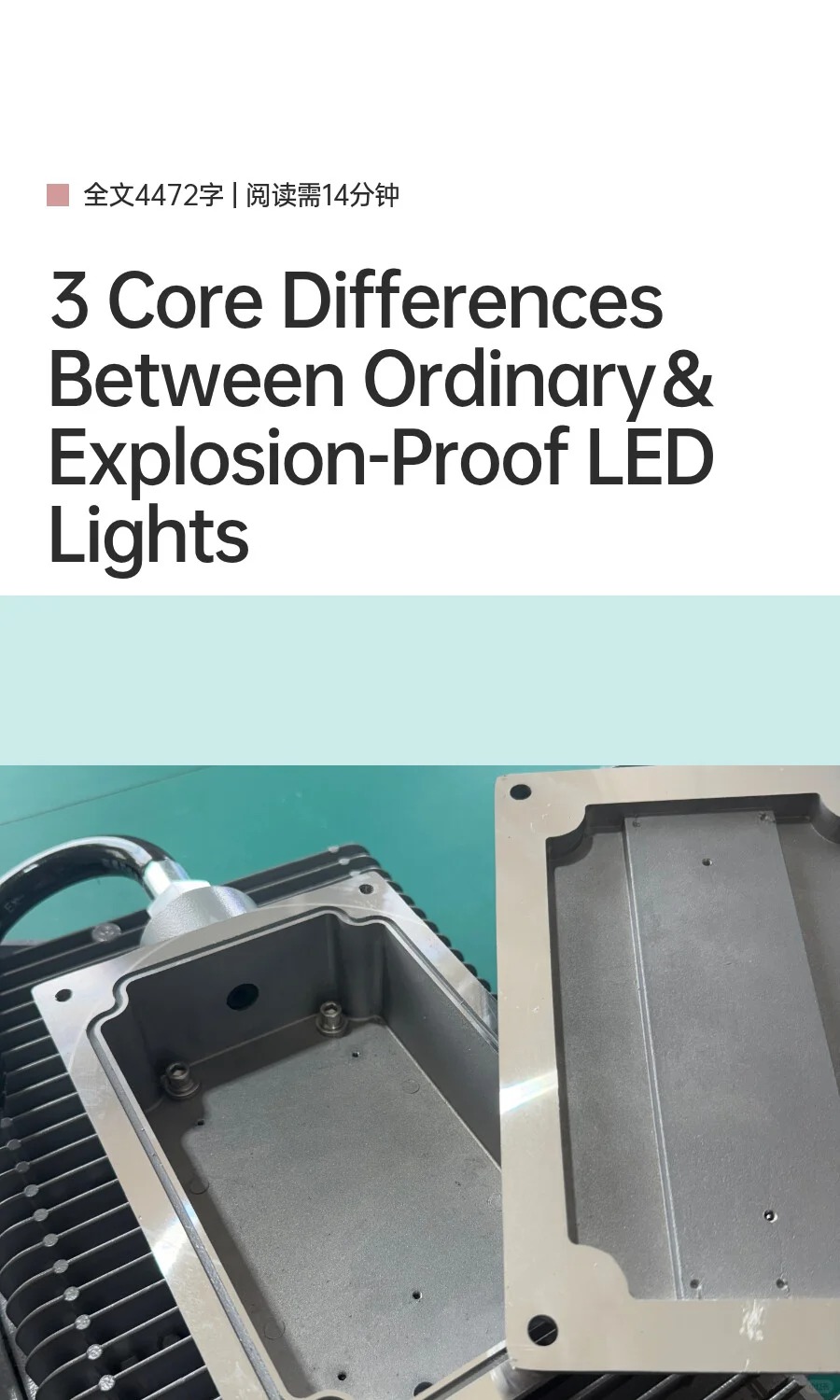

Explosion-proof lamps for chemical workshops have flameproof housings that can withstand 1.8 times the rated explosion pressure (50% higher than national standards), and intrinsically safe circuits can control energy below 10mJ in case of short circuits, completely blocking explosion risks.

As a recipient of the "China's Excellent Green Environmental Protection and Energy-Saving Product" certification, Royal's "green development" is not only reflected in the lamps themselves but also extended to the full-life-cycle energy efficiency optimization. Combined with intelligent technology, it achieves dual benefits of "energy saving + high efficiency":

The "energy saving" of Royal's data center-specific LEDs is systematic:

The lamps themselves have an electrical energy conversion rate of 96%, consuming 40% less energy than ordinary industrial LEDs;

Graphene microchannel heat dissipation design keeps the lamp surface temperature 3℃ lower than the ambient temperature, indirectly reducing additional air conditioning load. After application in a cloud data center, monthly air conditioning energy consumption saved by lighting reached 12,000 kWh, with an annual comprehensive energy saving of over 35%;

Lamp bodies are made of 92% recyclable aluminum alloy, and the material recovery rate after scrapping is far higher than the industry's average of 65%, reducing industrial solid waste pollution.

Royal deeply integrates lighting with the production logic of industrial scenarios and has developed an intelligent linkage system:

In automobile welding workshops, lamps can automatically switch color temperature in linkage with production rhythms—switching to 6000K cool white light during welding (to improve weld defect recognition rate) and 4000K neutral white light during assembly (to reduce visual fatigue);

In logistics warehouses, lamps are linked to the AGV robot positioning system. When a robot moves to a certain area, the corresponding lighting automatically increases brightness to 500lux, while the brightness in idle areas decreases to 100lux, reducing energy consumption by an additional 20%;

All intelligent lamps are connected to the industrial Internet of Things platform, supporting remote monitoring of lamp temperature and fault early warning.

Royal is well aware that there are no "one-size-fits-all" solutions for industrial scenarios. Therefore, it has built a "full-chain customized service system" to ensure each solution accurately meets customer needs:

Preliminary Research: Professional teams conduct on-site investigations to record workshop inspection routes, equipment electromagnetic sensitivity values, and temperature-humidity fluctuation ranges. When customizing cleanroom lamps for a pharmaceutical factory, even the GMP standard of "lamp bodies with no dead ends for easy cleaning" was taken into account;

Mid-Term Design: Adjust parameters according to scenario needs, such as adding "insect-proof nets" to prevent insect entry for food processing plants and "anti-glare shields" for outdoor municipal road lamps;

Post-Sales Maintenance: Relying on the five-star after-sales service system, it provides a 7-year warranty and regular on-site inspections.

From "micron-level protection" in semiconductor cleanrooms to "extreme environment adaptation" in desert oilfields, and then to "scenario-based linkage" in smart factories, Royal Lighting has always taken "innovation-driven customization" as its core. It has transformed lighting from a "supporting role" in industrial production into a "core enabler" for enhancing safety, optimizing efficiency, and practicing green development. In the future, Royal will continue to deepen its focus on industrial scenarios, using technology as a pen and customization as ink to continuously write the value story of "Made in China" in the industrial lighting track.