The main differences between explosion-proof lamps and platform lamps

1.Functions and uses Explosion-proof lamps: Mainly used in flammable and explosive hazardous environments (such as petroleum, chemical industry, coal mines, etc.). Its core function is to prevent sparks or high temperatures generated inside the lamp from causing external explosions.

Platform lamps: Suitable for places such as industrial platforms, corridors, equipment operation areas, etc. that require large-area high-brightness lighting. They emphasize durability and protection, but do not have explosion-proof capabilities.

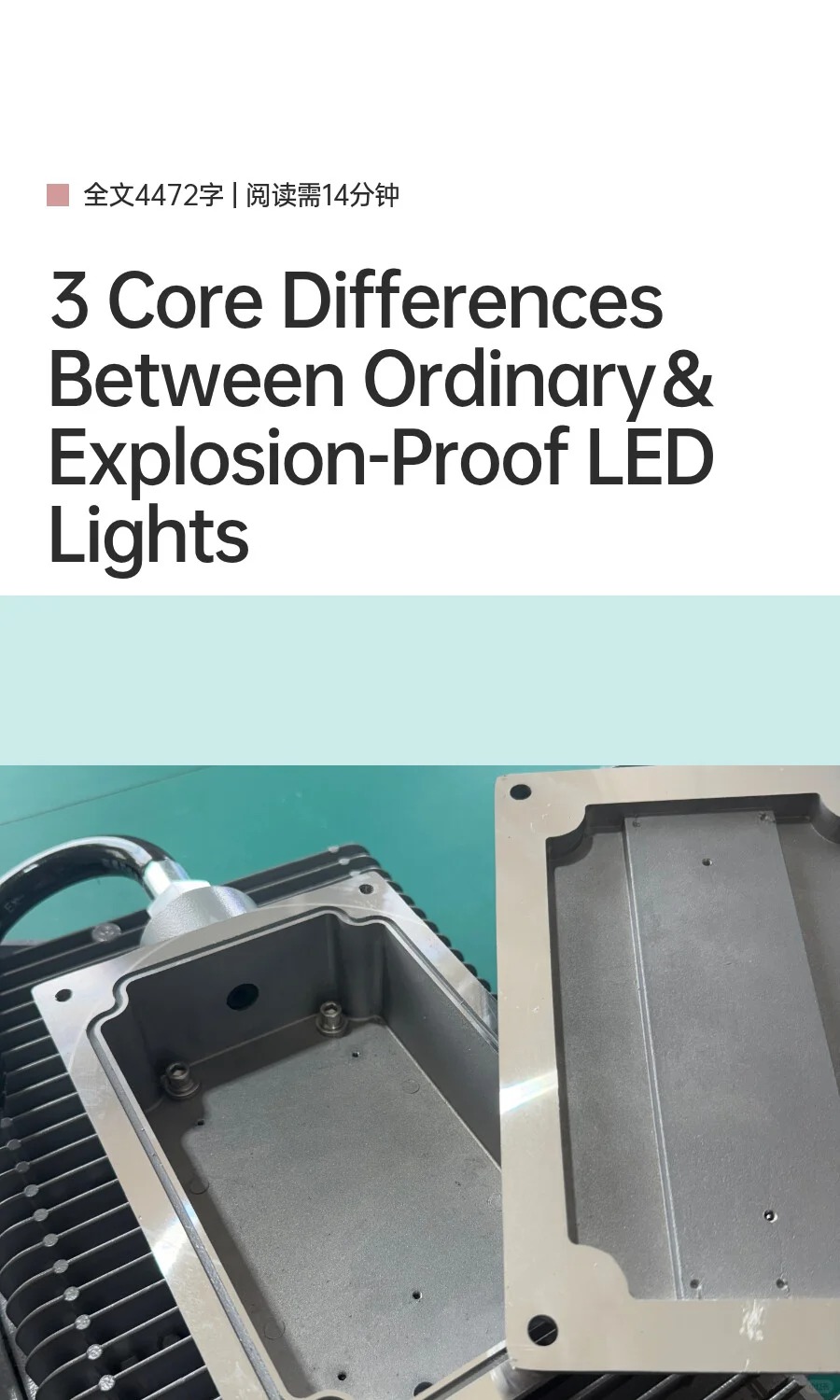

2.Applicable environment Explosion-proof lamps: Must be used in areas with explosion risks (such as oil depots and chemical plants) and must meet strict explosion-proof standards.Platform lamps: Suitable for ordinary industrial environments (such as workshops, warehouses, docks), and must have certain dust and water resistance (about IP65).

3.Structure and installation method Explosion-proof lamp: heavy shell (metal or high-strength plastic), strict sealing is required during installation (wall hanging, hanging or ceiling).Platform lamp: stable structure, mostly fixed by bracket, flange or hanging method, convenient for large area lighting.

4.Typical application scenarios Explosion-proof lamp: hazardous areas such as chemical plants, gas stations, mines, oil and gas pipelines.Platform lamp: factory workshop, dock loading and unloading area, stairwell, equipment operation platform

Summary Explosion-proof lamp: safety first, designed for hazardous environments.Platform lamp: high-intensity lighting, suitable for industrial fixed areas.

Choose the appropriate lamp according to the safety of the actual environment, lighting range and installation method.