## 防爆灯等级划分基础:防爆原理🧐

## 防爆灯等级划分基础:防爆原理🧐

To understand the level of explosion-proof lamps, you must first understand the principle of explosion-proof. It mainly limits the energy sources such as electric sparks and high temperatures that may be generated in the lamps🔥, preventing the ignition of surrounding flammable and explosive materials. Common explosion-proof technologies include flameproof type (d), increased safety type (e), intrinsic safety type (i), etc.

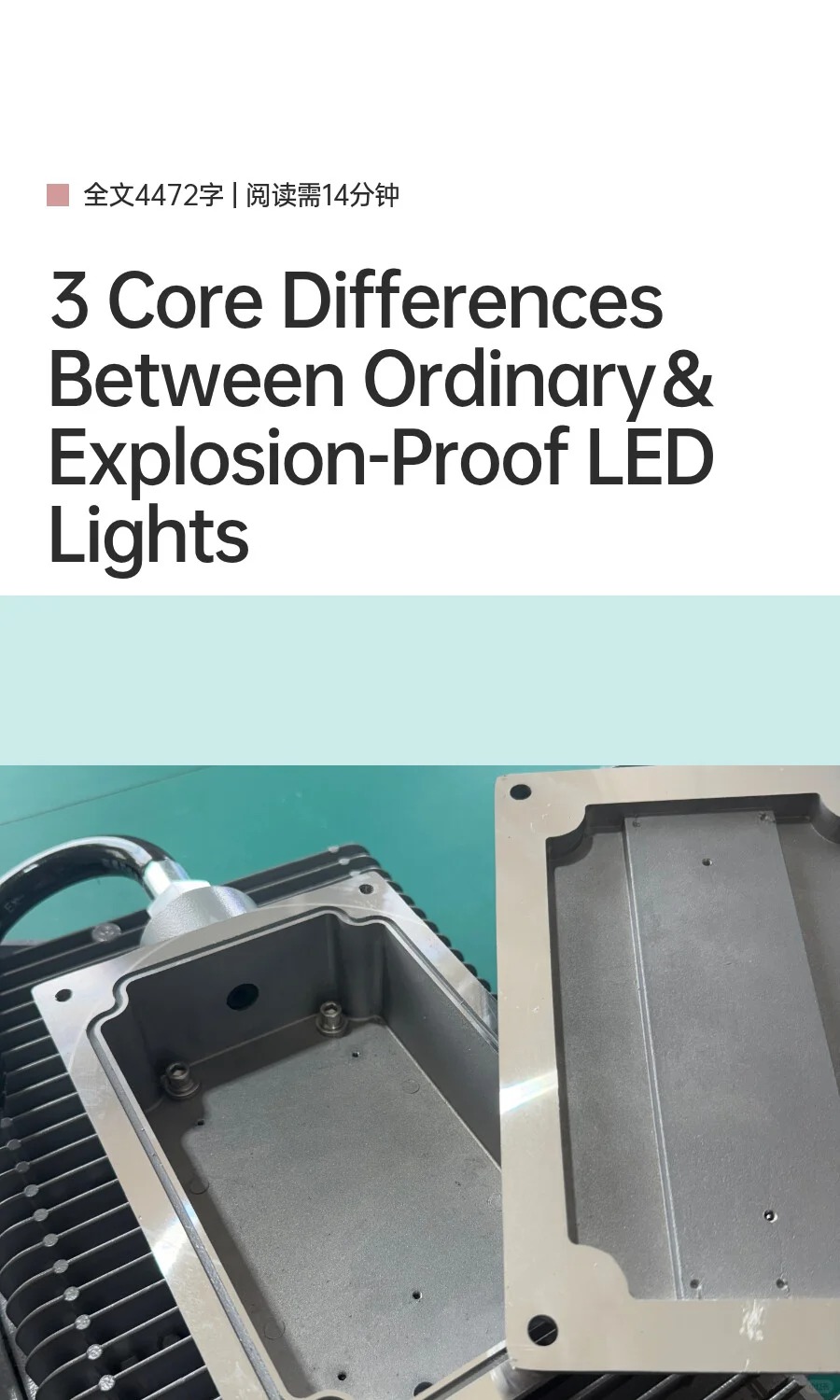

### Flameproof type (d)🛡️

Explosion-proof lamps use a solid shell to separate internal electrical components from dangerous gases. When an internal explosion occurs, the shell can withstand pressure, prevent flames and hot air from expanding outward, and avoid igniting surrounding gases. Its shell is often made of high-strength metal, with high mechanical strength and good sealing.

### Increased safety type (e)💪

In normal operation, increased safety explosion-proof lamps improve safety by insulating live parts and limiting surface temperature. They are also often equipped with short-circuit and overload protection devices to further improve the safety factor.

### Intrinsically safe (i)⚡

The core of intrinsically safe explosion-proof lamps is to limit the energy of the circuit, so that the electric sparks and thermal effects in normal and fault conditions are not enough to ignite explosives. It adopts low voltage and low current circuit design, ensures intrinsic safety through special measures, and is suitable for the most dangerous places.

## Explosion-proof lamp classification system📊

It is mainly divided according to gas group and temperature group.

### Gas group🎯

It is divided according to the minimum ignition current ratio (MICR) and maximum test safety gap (MESG) of different flammable and explosive gases. Common ones are I, IIA, IIB, IIC, etc.

- **Class I**: used in coal mines with methane, specially designed to prevent methane explosions.

- **Class II**: used in other industrial places, further subdivided:

- **Class IIA**: suitable for low-risk gas environments such as propane.

- **Class IIB**: suitable for medium-risk gases such as ethylene.

- **Class IIC**: used in highly hazardous gas environments such as hydrogen and acetylene, with the highest explosion-proof performance requirements.

### Temperature group 🌡️

According to the maximum surface temperature of explosion-proof lamps, there are 6 groups from T1 to T6.

- **T1**: The maximum surface temperature does not exceed 450℃.

- **T2**: Does not exceed 300℃, the temperature group increases, and the requirements for heat dissipation and temperature control are stricter.

- **T3**: Does not exceed 200℃.

- **T4**: Does not exceed 135℃.

- **T5**: Does not exceed 100℃.

- **T6**: Does not exceed 85℃, with the highest requirements, suitable for temperature-sensitive environments.

## How to choose the right level of explosion-proof lamp 🤔

In actual applications, the selection of lamps should comprehensively consider the type, concentration and ambient temperature of flammable and explosive substances. First determine the type of substance, and select the lamp according to the gas and temperature group. For example, in a chemical workshop with hydrogen, since hydrogen belongs to Class IIC and has high temperature, you may need to choose Class IIC, T3 and above explosion-proof lamps.

You should also pay attention to the certification status. Regular products should have Ex certification and other signs, which is a proof of compliance with the standards. Be sure to choose certified products.

In short, the classification of explosion-proof lamps is complex and rigorous, and it is related to the lighting safety in hazardous places. Understanding this knowledge can help us choose the right lamp, prevent explosion accidents, and ensure the smooth progress of production and life. 💯

#Explosion-proof lamp #Grade classification #Safe lighting #Explosion-proof knowledge