**一、引言**

**一、引言**

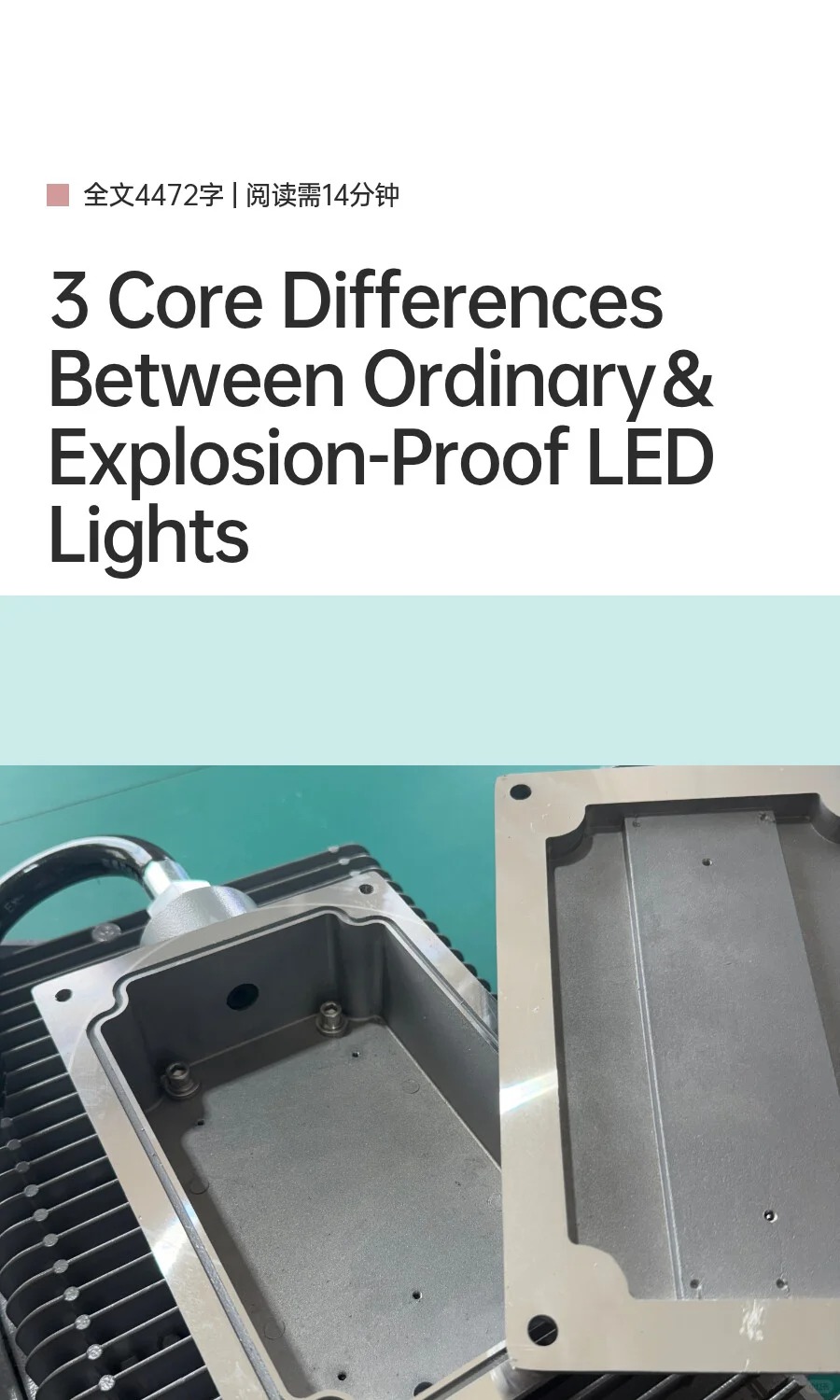

In some special places, due to the presence of flammable and explosive substances or environments, ordinary lighting fixtures may cause serious safety accidents. Therefore, explosion-proof lamps came into being as a special lighting equipment. Explosion-proof lamps can work safely and reliably in dangerous environments, provide necessary lighting for personnel, and ensure the normal progress of production and operations.

**Second, places suitable for using explosion-proof lamps**

1. Petrochemical industry

- There are a large number of flammable liquids, gases and steam in places such as refineries, chemical plants, and oil depots.

- In these areas, the explosion-proof level is usually required to be higher to prevent sparks, high temperatures, etc. from causing explosions.

2. Coal mining industry

- There are flammable gases such as gas in the mines, which are prone to explosion accidents.

- Lamps with specific explosion-proof levels need to be selected to adapt to the harsh environment in coal mines.

3. Pharmaceutical industry

- Flammable and explosive solvents and chemicals are used in some pharmaceutical processes.

- Explosion-proof lamps need to be installed in production workshops and storage areas.

4. Grain processing industry

- Grain dust may explode under certain conditions, such as flour mills, feed mills, etc.

- Lighting equipment must have explosion-proof performance.

5. Ship industry

- Fuel and flammable gases exist in the engine room, oil tank and other parts of the ship.

- Explosion-proof lamps can ensure lighting safety when sailing at sea.

**III. Differences in site classification and explosion-proof grade requirements**

1. Gas environment

- According to the type and concentration of flammable gas, it is divided into different hazardous areas, such as Zone 0, Zone 1 and Zone 2.

- Zone 0 is the most dangerous area, requiring explosion-proof lamps to have the highest explosion-proof grade; Zone 1 is second; Zone 2 is relatively less dangerous, and the explosion-proof grade requirements are also reduced accordingly.

2. Dust environment

- It is also divided into Zone 20, Zone 21 and Zone 22.

- Zone 20 has the highest dust concentration and the most stringent explosion-proof requirements.